Accelerating the circular sharing of standardized pallets is of great significance

In China, the use of pallets is mostly through internal turnover within enterprises, commonly using the practice of loading goods onto vehicles and not leaving the factory with pallets. Although the goods are repeatedly overturned during transit, which consumes manpower and is prone to damage, there is no better method. The use of low-cost disposable pallets can solve problems to a certain extent, but it will result in huge resource waste. Therefore, disposable pallets are currently mostly used for international and long-distance transportation and are difficult to widely promote and use. In this case, a socialized organizational approach should be adopted to address the recycling and recycling of pallets. Many developed countries have established pallet sharing systems, which can achieve the circular use of pallets throughout society, greatly improving the operational efficiency of supply chain logistics.

1、 Logistics equipment standards involved in pallet sharing systems

At present, there are many logistics equipment standards involved in the tray recycling and sharing system, including tray standards, logistics transportation vehicle standards, warehouse shelf standards, and so on. In addition, in order to facilitate the smooth implementation of the tray recycling and sharing system among upstream and downstream enterprises in the supply chain, in addition to reaching consensus among cooperating enterprises, it is also necessary for each node of the entire supply chain to have a unified standard and standardized process in product standards, transportation tools, handling equipment, storage facilities, etc., including tray specifications, quality acceptance standards, recycling and sharing operation specifications, service specifications, transportation vehicle standards, forklift standards, and shelf specifications. With the rapid development of the logistics industry and its increasingly important impact on the national economy, logistics standardization work has become increasingly urgent.

At present, national and industry standards related to the pallet industry include: "Main dimensions and tolerances of general flat pallets for intermodal transportation", "Performance requirements and test selection of general flat pallets for intermodal transportation", "General flat pallets for intermodal transportation", "Test methods for general flat pallets for intermodal transportation", "Pallet coding and barcode representation", and so on. However, these standards do not involve the management of tray recycling sharing. In order to fill this gap, the National Standards Commission and the Ministry of Commerce and other departments have approved the project and are developing a series of standards and industry norms related to tray recycling and sharing, including the "Operation Specification for Tray Sharing System", "Identification System for Shared System Trays", "Quality of Plastic Flat Trays in Shared System", "Load Dimensions and Load of Shared System Tray Units", "Requirements for Shared System Trays", "Requirements for Handling Equipment of Shared System Trays", "Requirements for Storage Facilities of Shared System Trays", "Management Specification for Shared System Trays", "Application Specification for Electronic Labels in Shared System Trays", and "Information Management Specification for Shared System Trays".

2、 The value of tray sharing system mode and standardization

In recent years, many international and domestic companies have been exploring the market of shared tray services in China, such as China Merchants Lukai, Jibao, Quanya, and so on, each with its own advantages and characteristics.

Taking China Merchants Lukai as an example, the company has over 70 years of rich experience in the logistics packaging equipment leasing industry, headquartered in Hong Kong, and its business is divided into three regions by region: Greater China, Southeast Asia, and Australia. As of the end of 2014, China Merchants Lukai has become the largest tray recycling service provider in Greater China, serving customers such as manufacturers, distributors, logistics providers, and retailers in the upstream and downstream of the supply chain. It advocates for the development of the cargo transportation model with pallets through shared leasing and management of logistics packaging equipment, in order to improve customer logistics efficiency and reduce the difficulty of equipment management.

Regarding the tray recycling and sharing mode, China Merchants Lukai believes that it should be divided into alliance pool mode and commercial pool mode, with the European Pallet Association (EPAL) being a typical alliance pool mode. However, the tray maintenance of the Alliance Pool cannot achieve economies of scale, tray quality is difficult to control, retailer tray exchange is difficult, and regulatory costs are high, resulting in the inability of this model to develop on a global scale. The Canadian Pallet Association (CPC), which uses the Alliance Pool model, even eventually disintegrated. At present, most tray recycling and sharing systems in regions around the world, including Greater China, Southeast Asia, the United States, Japan, South Korea, Australia, etc., are mainly based on commercial pool models, among which China Merchants Lukai is a leading commercial pool operator in the Asia Pacific region.

In the tray recycling and sharing system, standardization can bring enormous value to application enterprises. China Merchants Lukai believes that the cost savings of pallet recycling and sharing mainly come from transportation with pallets. The biggest advantage of plate transportation is that it saves warehouse space by improving inbound and outbound efficiency, and saves loading and unloading costs through mechanized operations. Taking the fast-moving consumer goods industry as an example, within a transportation distance of 150 kilometers, with reasonable optimization of order mode, plate making method, and loading method according to the requirements of plate transportation, the total logistics cost can be saved by 2% to 22% through plate transportation.

Before the tray recycling and sharing, a large fast-moving consumer goods retail enterprise had a huge contrast with the efficient palletized warehousing and automated order picking operations in its backend, as the vast majority of upstream suppliers adopted a loose box delivery model. The unloading efficiency of loose containers is very low, and unloading a truck often takes several hours. Even if the goods are transported on pallets, they still need to be transported from the supplier's pallet to the retailer's pallet, resulting in very low overall efficiency. As a result, suppliers often complain about slow delivery. For fast-moving consumer goods logistics centers that pursue fast in and out, receiving docks are scarce resources, and the receiving efficiency of logistics centers often depends on the utilization rate of receiving docks, because the business volume grows rapidly every year, especially in the past two years, low receiving efficiency has become a bottleneck affecting the overall efficiency improvement of enterprises.

After joint discussion and analysis with China Merchants Lukai, as well as upstream suppliers and partners, it was found that tray recycling and sharing can greatly improve efficiency. Therefore, the retailer decided to take the lead in promoting tray recycling and sharing projects in the supply chain. In addition, tray recycling can also reduce the rate of product damage. Previously, upstream suppliers had to manually stack their loose box products on standardized pallets prepared by the retail logistics center, which undoubtedly increased the risk of product damage. If the proportion of palletized delivery from existing suppliers can be increased, it will undoubtedly improve the receiving efficiency of logistics centers and reduce product losses.

After more than half a year of operation, tray recycling and sharing have saved the retailer 90% of receiving time, reduced damage rates by 50%, and reduced inventory turnover by 29%. Overall, tray recycling reduces supply chain costs by 15% to 20%.

3、 Process analysis of tray recycling and sharing system

Due to the fact that plate transportation between upstream and downstream enterprises in the industrial chain is a prerequisite for the recycling and sharing of pallets, more and more food, grain and oil, daily chemical, and beverage enterprises are starting to implement plate transportation. However, tray recycling and sharing is not simply about placing products on pallets for transportation. It is necessary to establish an operational process suitable for transportation with pallets.

Through observation, China Merchants Lukai found that the main problem that needs to be solved in the process of domestic tray recycling and sharing is the optimization of the transportation process with pallets, which includes process integration, standardization of stacking standards (TIHI), information synchronization, and incentive policies for transportation with pallets.

Ordering mode: In the transportation mode with boards, in order to avoid higher warehouse operations and transportation costs caused by the product in the circulation process, it is necessary to place orders as much as possible in units of whole boards, half boards, or whole layers.

Process integration: Process integration can accelerate the efficiency of receiving and picking goods in retail logistics centers (DCs), reduce the time it takes for goods to occupy the receiving channel, and reduce the number of operators. For example, for suppliers with large order volumes and a large number of items, different assembly modes can be adopted based on order information. At the same time, transportation with pallets places higher demands on the synchronization and accuracy of information flow between retailers and suppliers, as the immediacy and accuracy of information transmission greatly affect the receiving efficiency of retailer DCs.

Stacking Standards (TIHI): It is very important to unify the TIHI standards because inconsistent TIHI can result in flipping operations and additional manual handling costs. Therefore, before the launch of the transportation project with plates, both the supplier and the supplier need to have sufficient communication on the TIHI standards for overstocking and inventory products.

Receipt and inspection mode: Retailers should provide support to suppliers who transport goods with pallets in terms of receipt and inspection. Mainly in terms of inspection methods, different inspection methods are adopted for goods transported with pallets to accelerate the receiving speed; And provide a green channel, prioritizing the arrangement of receiving channels for goods transported with pallets to accelerate vehicle turnover; Handling tools should also be provided for transporting goods with pallets to further reduce the unloading costs for suppliers.

Vehicle loading rate: Transportation with pallets can reduce the loading rate of transportation vehicles to a certain extent, but optimizing vehicle selection and palletizing methods can effectively reduce the loss of loading rate. The lack of unified domestic vehicle model standards poses certain difficulties for pallet transportation operations. Choosing appropriate vehicle models or modifying existing vehicles to make them more suitable for pallet transportation can improve the pallet loading capacity and utilization rate of vehicles. In addition, stacking or raising different goods and transportation vehicles on the pallets can also improve the loading rate.

Incentive policy: For enterprises that have previously used non-standard equipment, transportation with plates will increase the cost of equipment replacement or renovation. In order to vigorously promote the development of tray recycling and sharing, the Ministry of Commerce officially issued the "Special Action Plan for Standardization of Commercial Logistics" in December 2014, and China Merchants Lukai became the first batch of key promoted enterprises. This plan provides subsidies for standardized logistics equipment service providers to expand their leasing business, strengthen the management, upgrading, and market development of standardized equipment; For non-standard tray standardization updates, subsidies will be provided by increasing the use of standard trays; At the same time, subsidies will also be provided for non-standard shelves, forklifts, warehouses, and related supporting facilities and equipment updates and renovations of pallet using enterprises.

Overall, the construction of a standardized pallet recycling and sharing system not only helps enterprises save costs, but also effectively ensures the safety of transported goods. With the continuously rising labor and land costs, the concentration of retail formats has increased, and inventory and replenishment management continues to be optimized, the tray recycling and sharing system has ushered in a historic period of development opportunities. At the same time, taking the standardization of logistics equipment such as pallets and shelves as a breakthrough point to achieve the improvement of logistics efficiency in the whole society will also bring important significance to the reduction of total logistics costs in China.

-

-

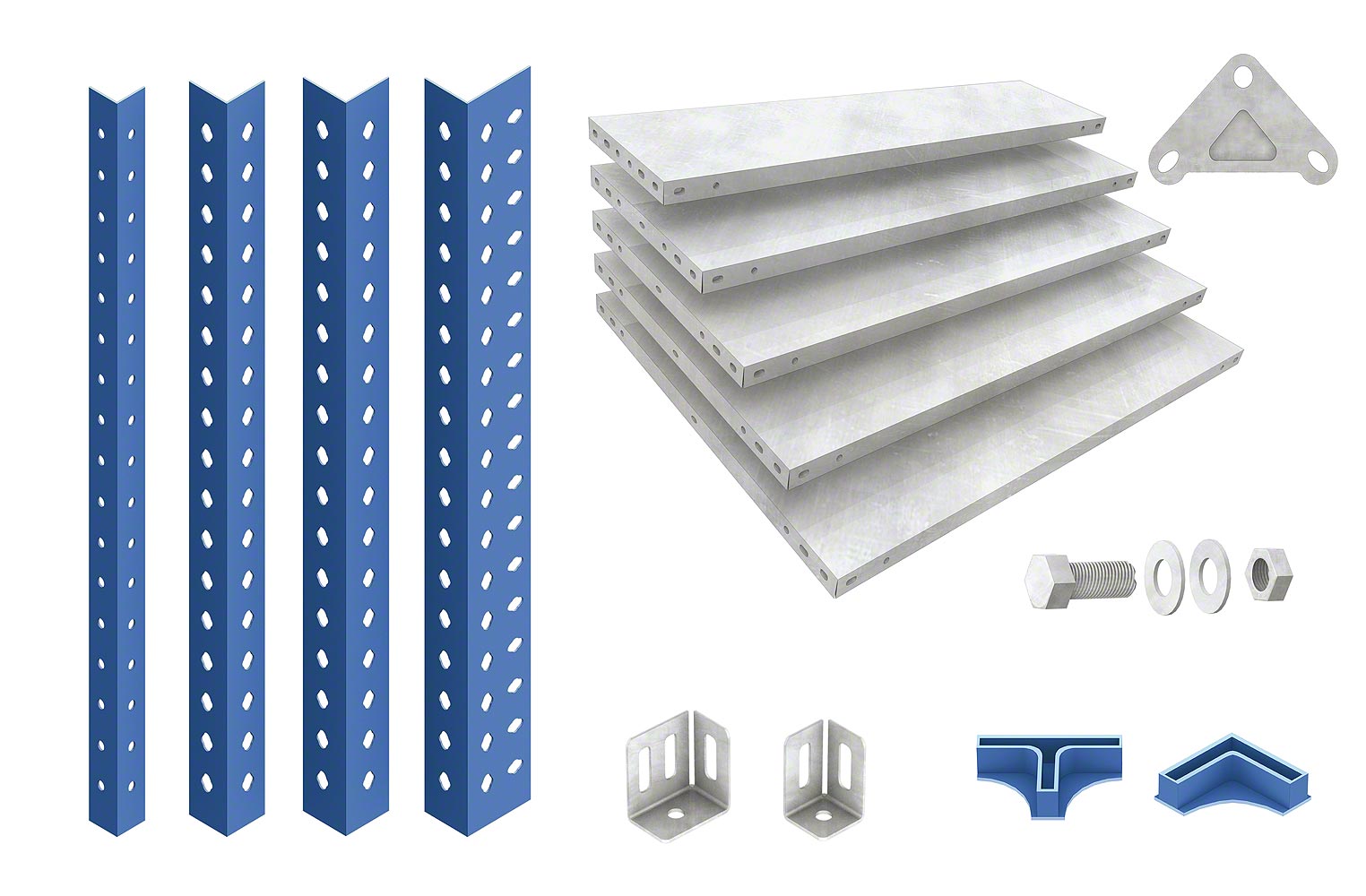

The difference between metal warehouse shelves and wooden shelves

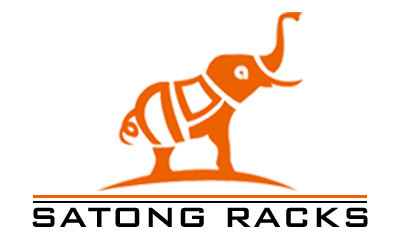

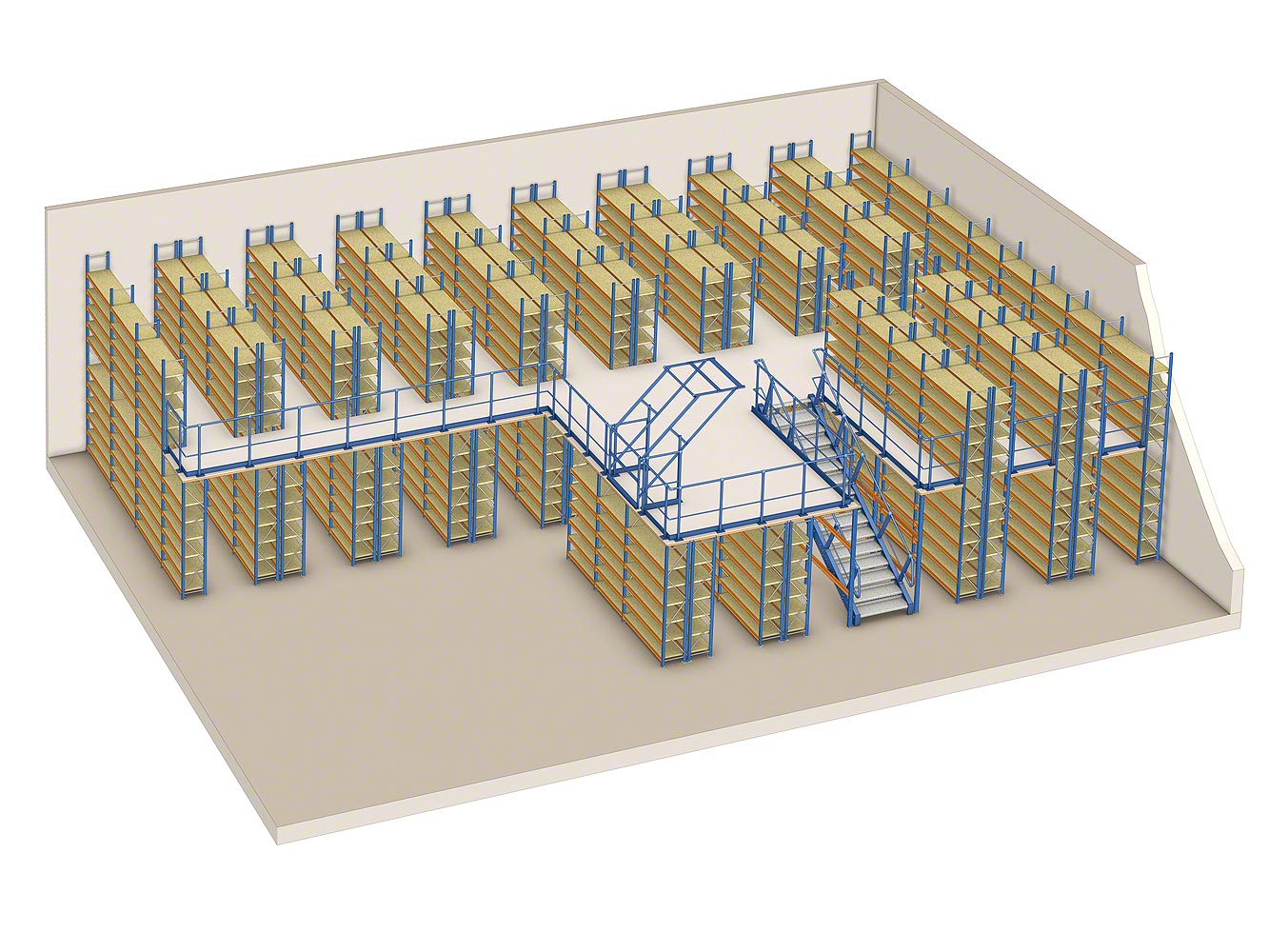

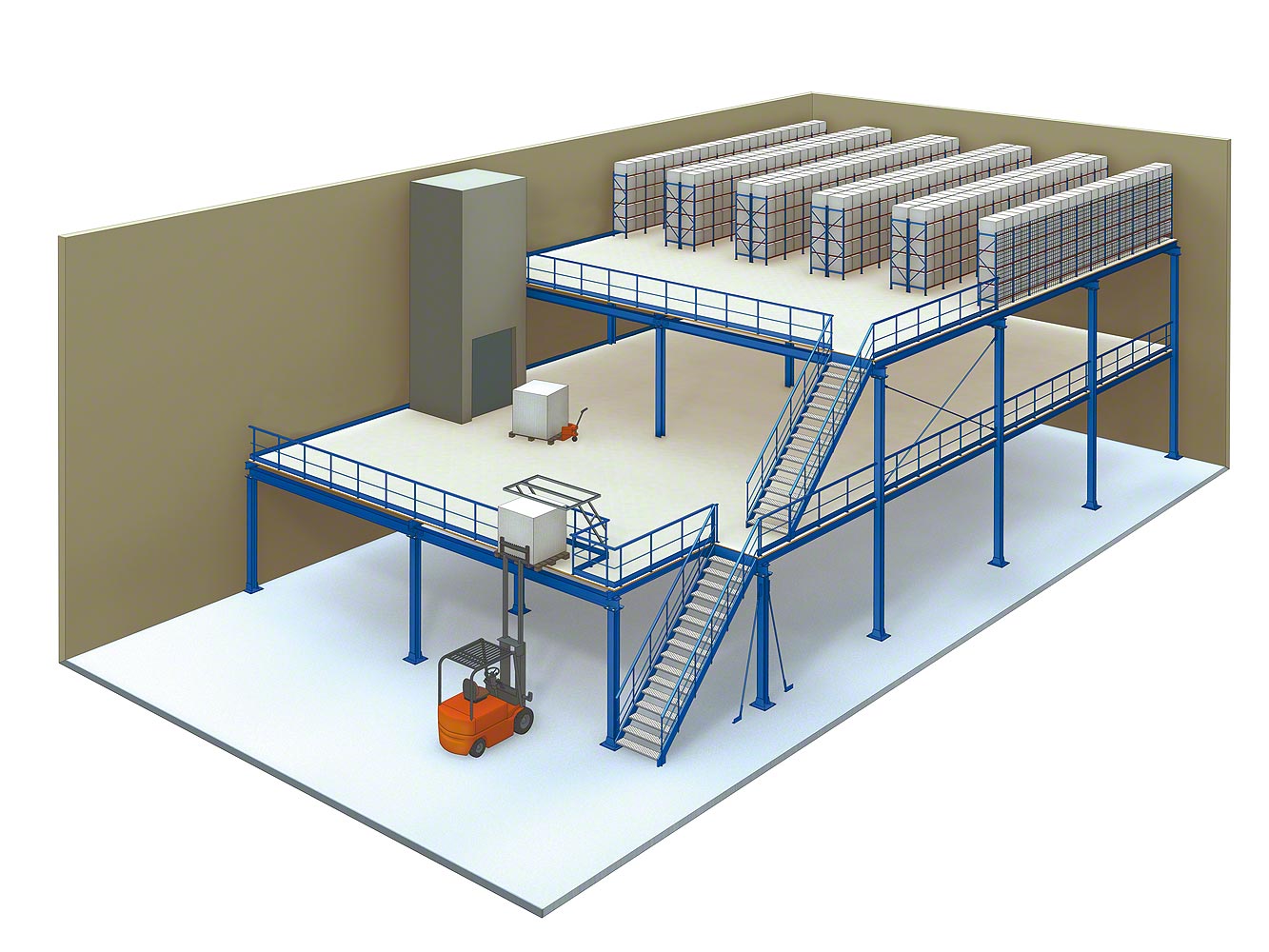

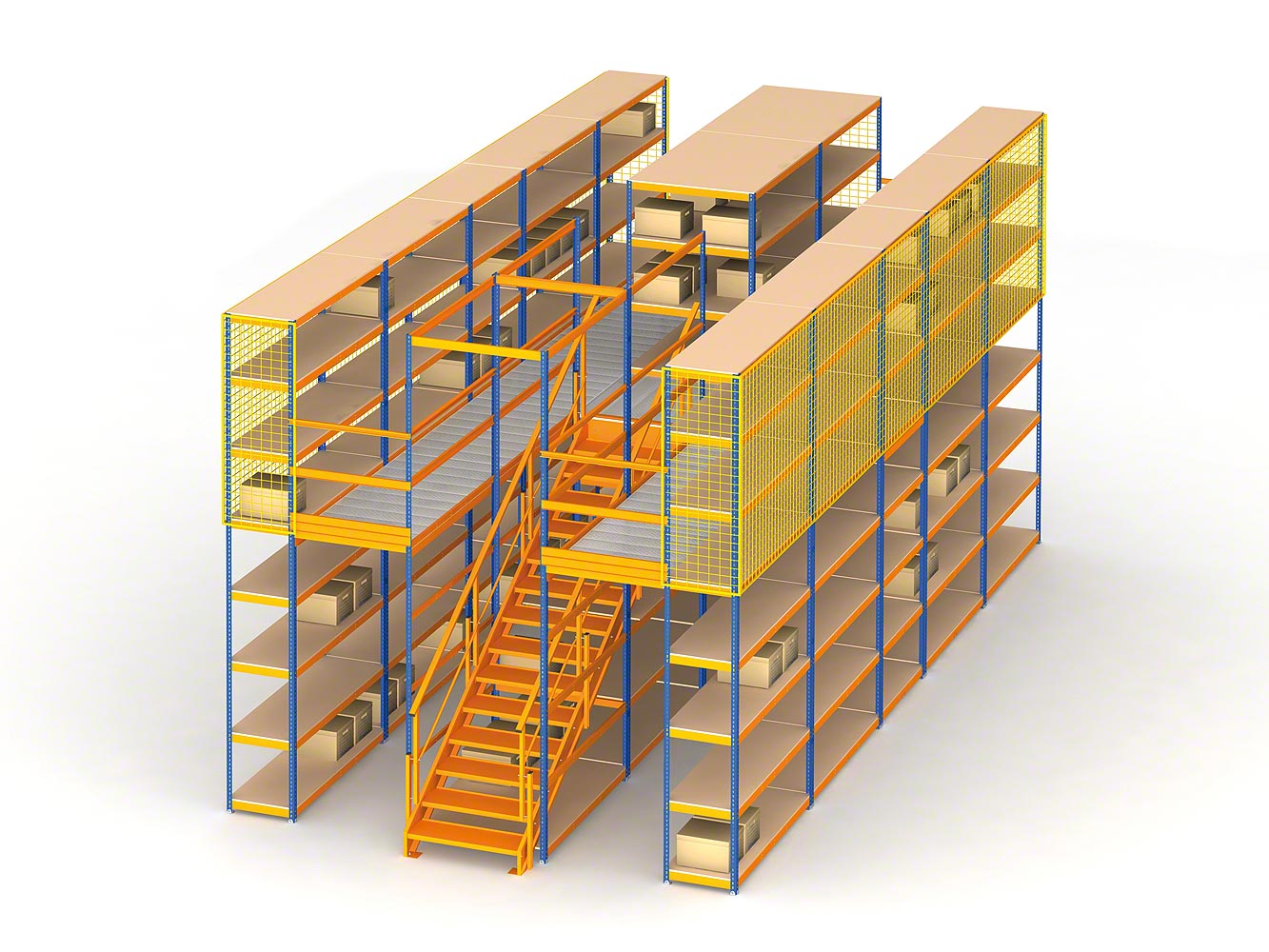

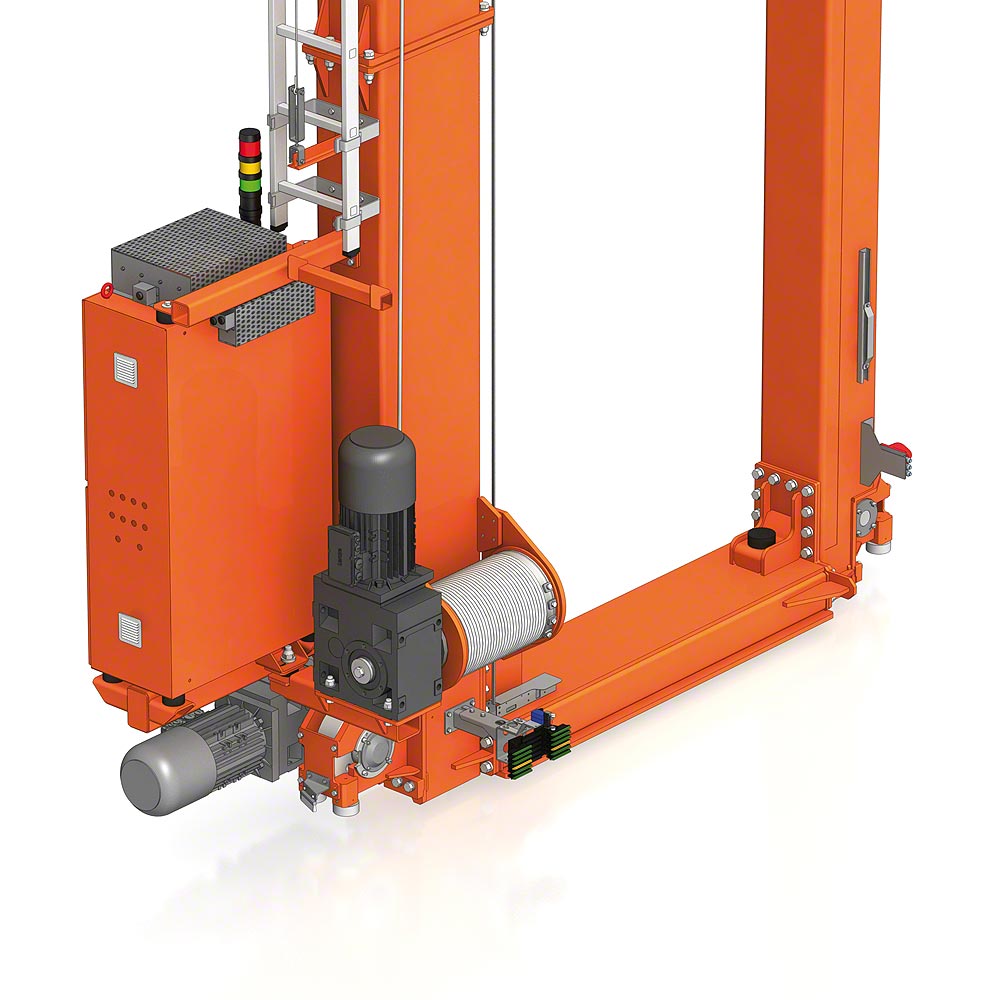

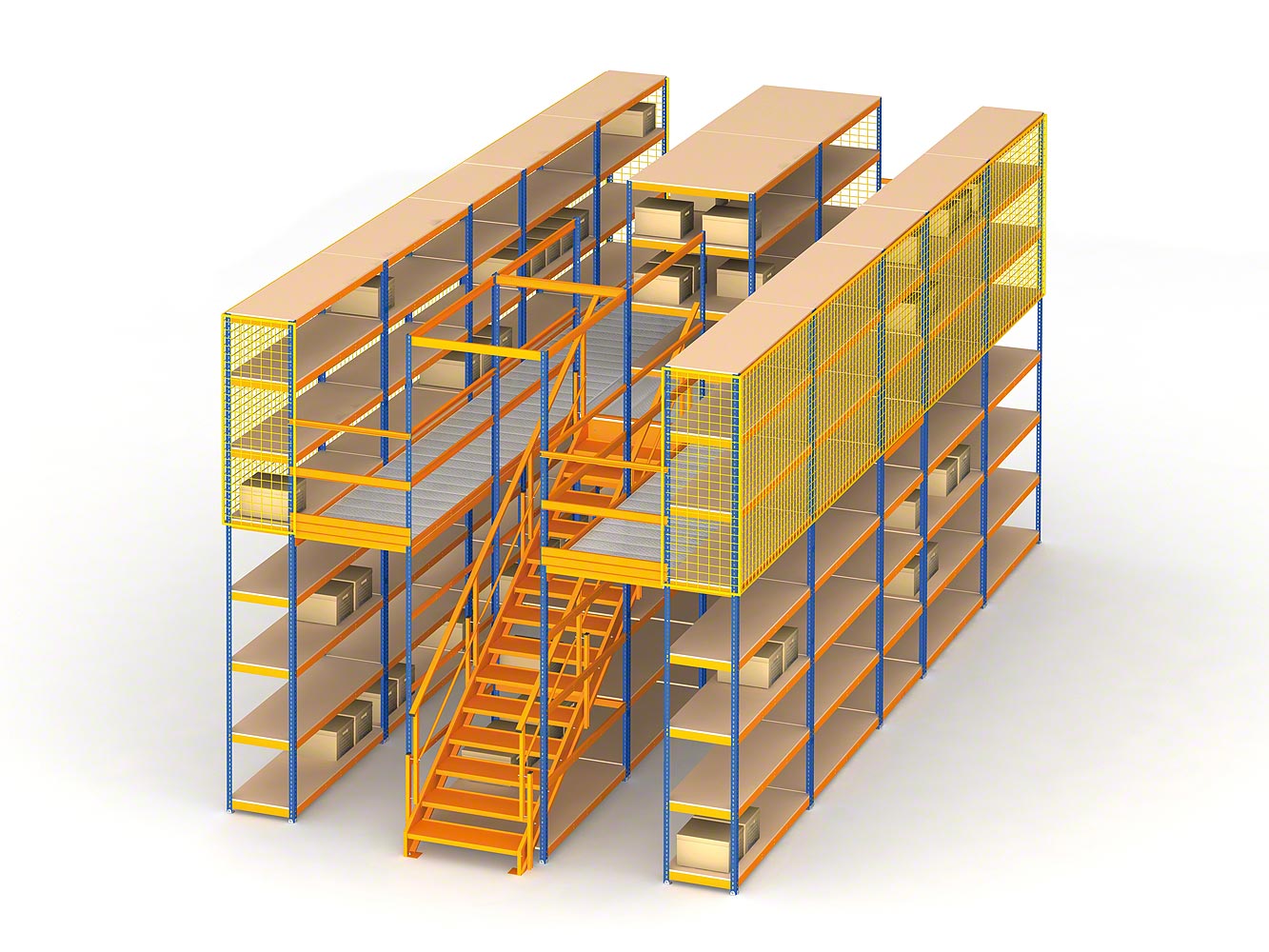

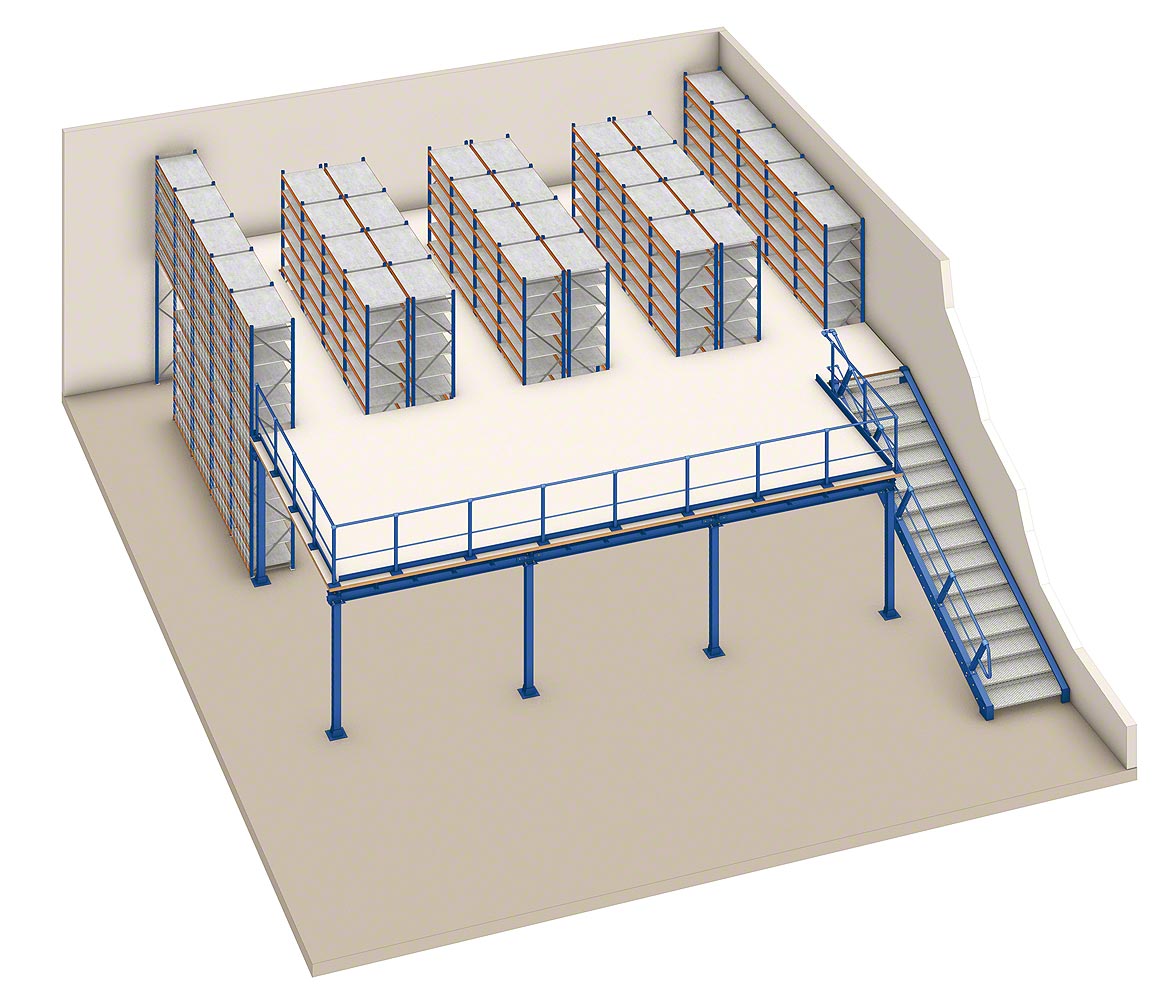

Penthouse style shelves are used as floor support and can be designed as multiple floors (usually 2-3 floors) with stairs and cargo elevators. They are suitable for high storage rooms, light and small goods, and manual access. When there is a large storage capacity, use elevators and hydraulic lifting platforms.

-

Pure dry goods, come and take a look. You don't know anything about shelves

For supermarkets, shopping malls, warehouses and other places, Xuzhou shelves are very important storage equipment, which can play a good role in organizing and storing. In the use of shelves in Xuzhou, it is necessary to reduce damag

-

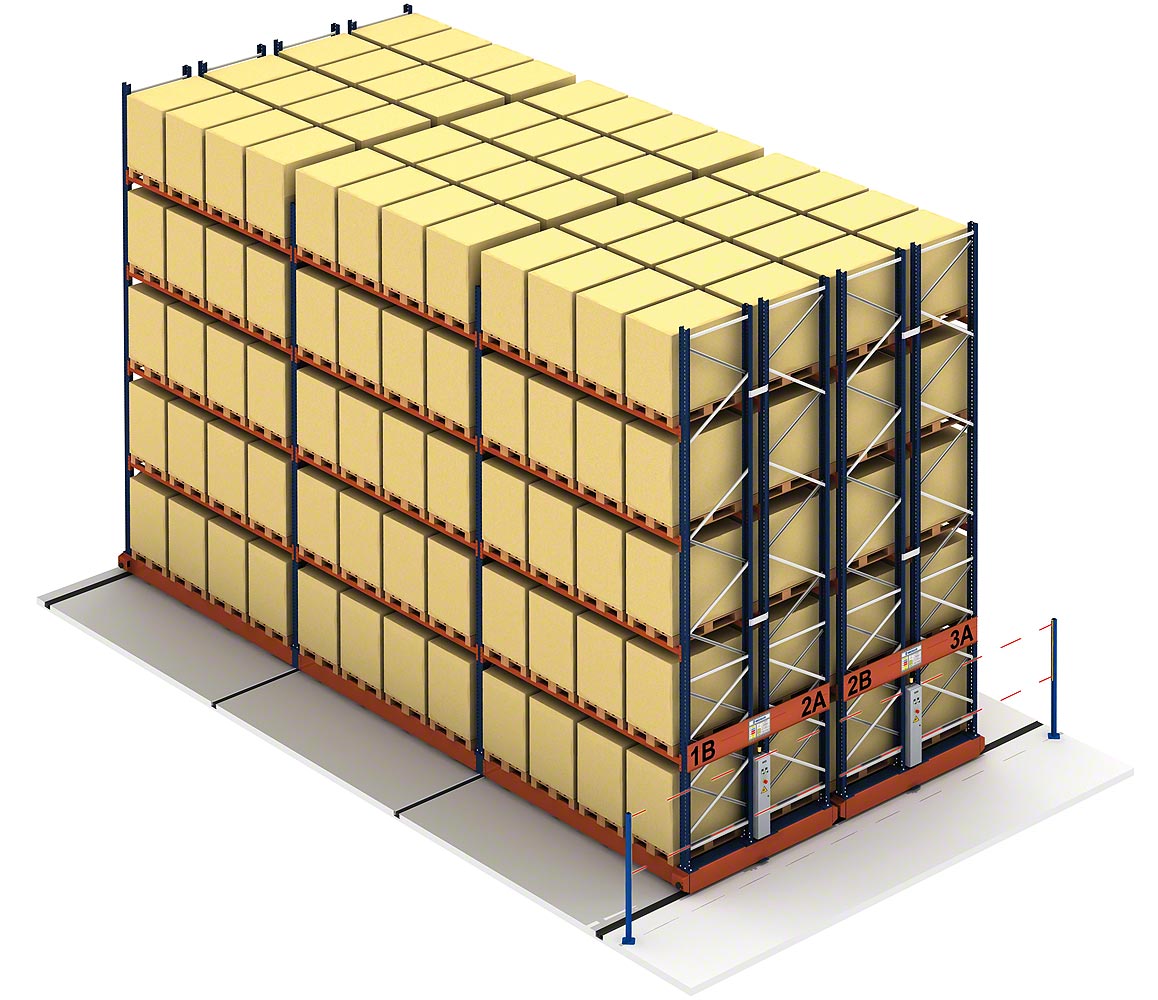

The difference between crossbeam shelving and through shelving

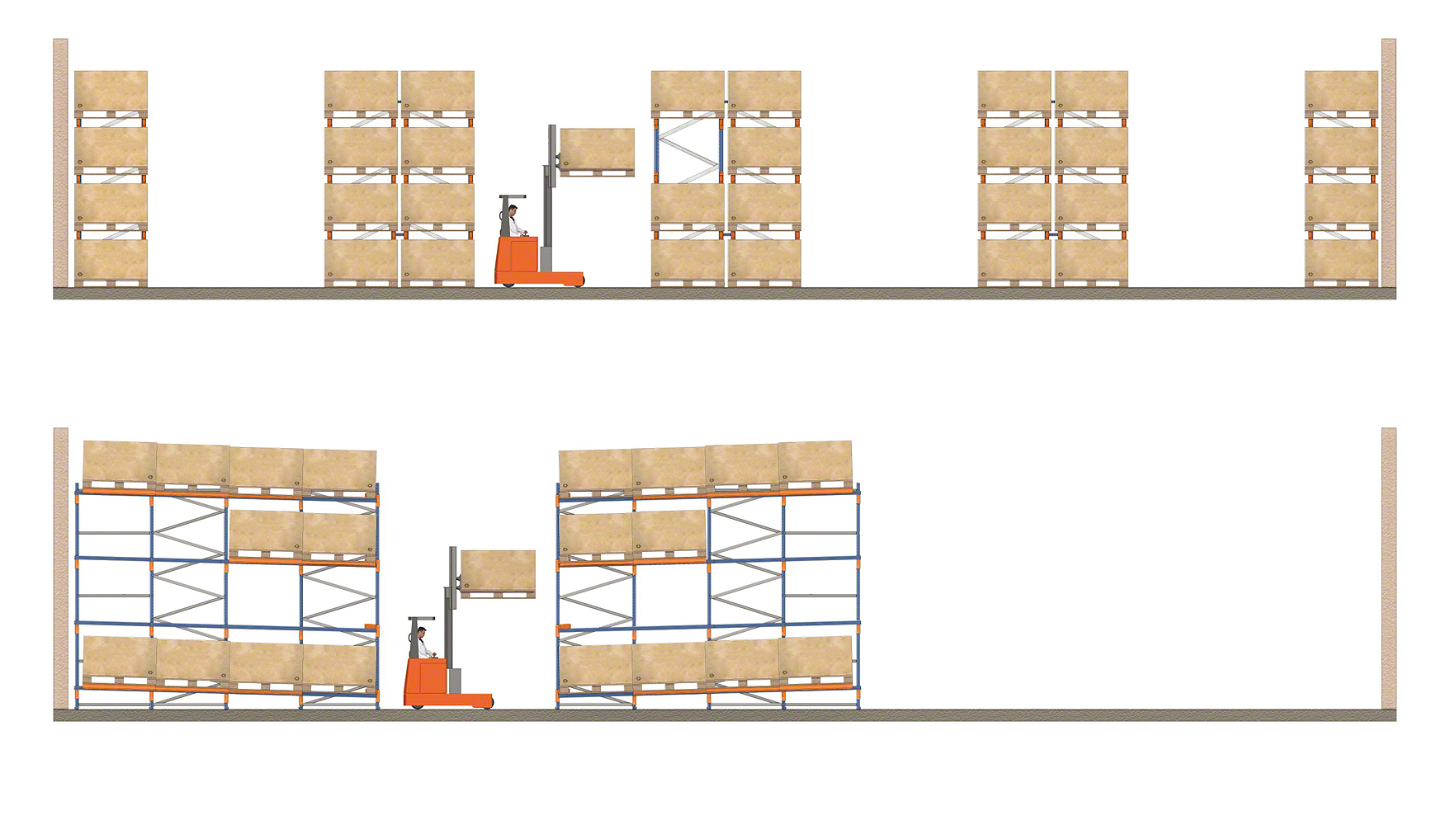

Cross beam shelving is a professional warehouse shelving designed for storing and retrieving palletized goods (each pallet is a storage space, hence also known as a storage space shelving);

-

What are the advantages of shelves compared to traditional stacking?

The shelf is a modular structure that fully utilizes space. Penthouse style shelves play a very important role in modern logistics activities. The modernization of warehouse management is directly related to the type and function of shelves.

-

Certificates

ISO900,ISO45001,ISO14001,CE

-