(China) Jiangsu Satong Intelligent Logistics Equipment Co., Ltd

-

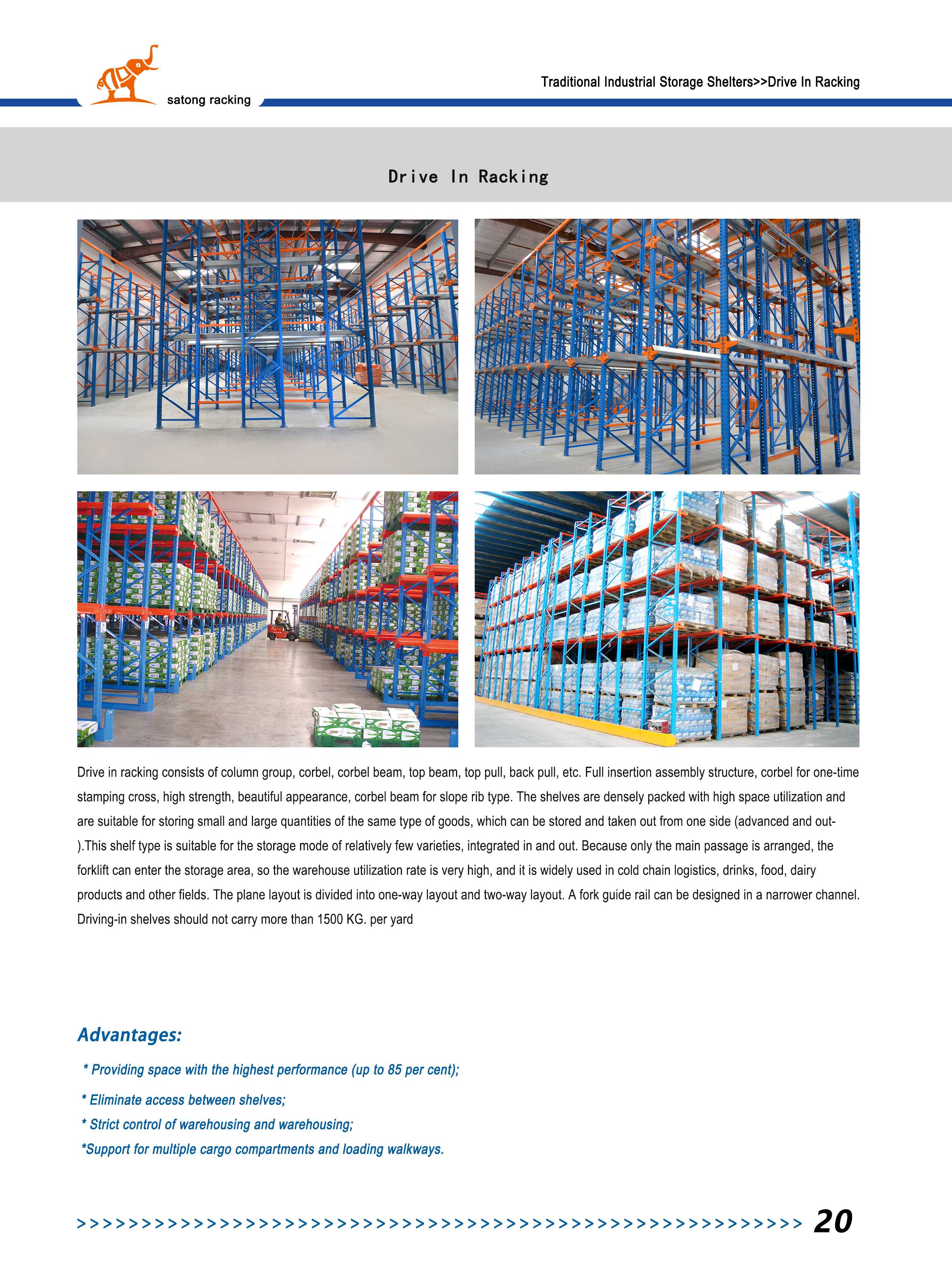

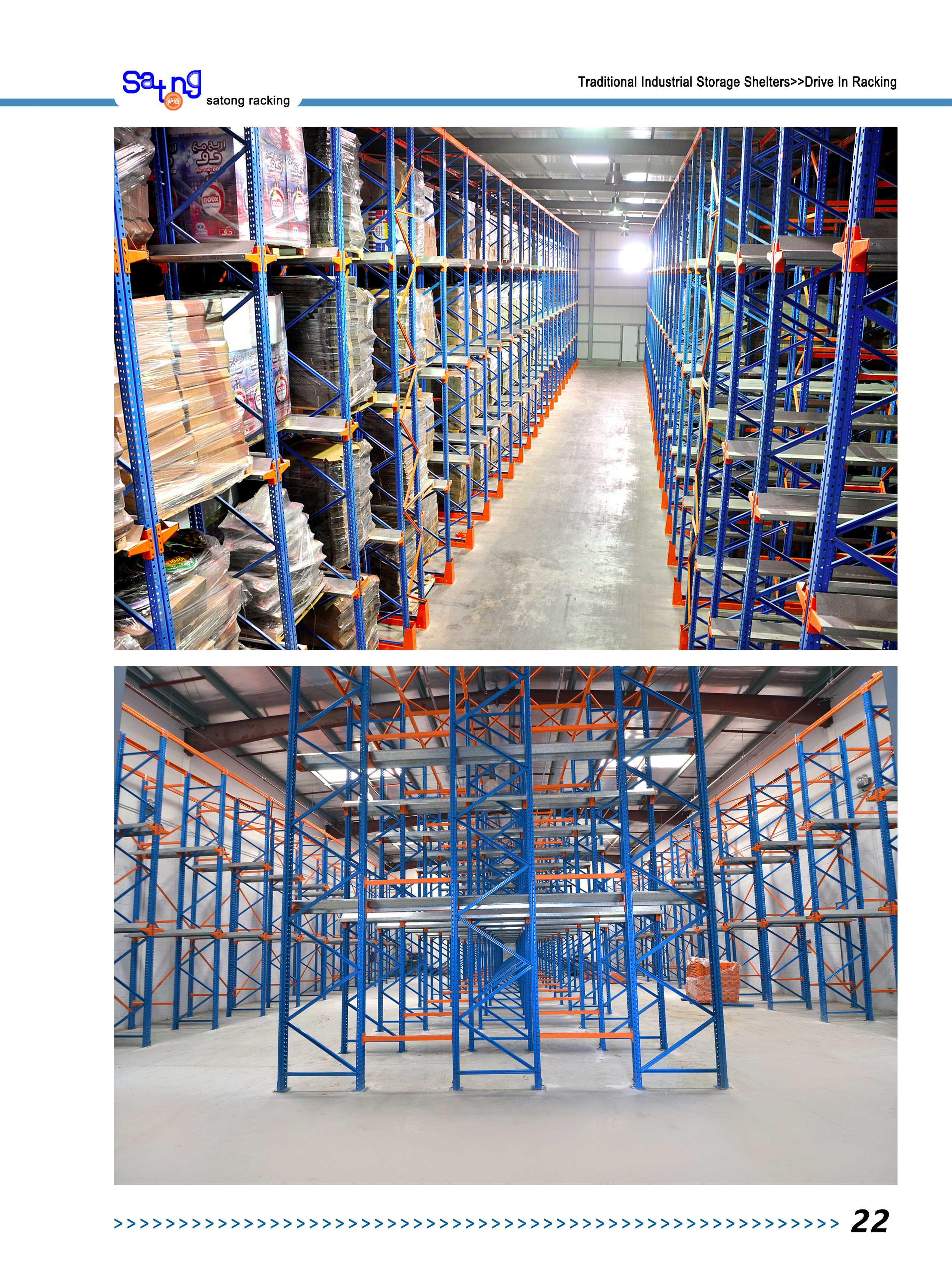

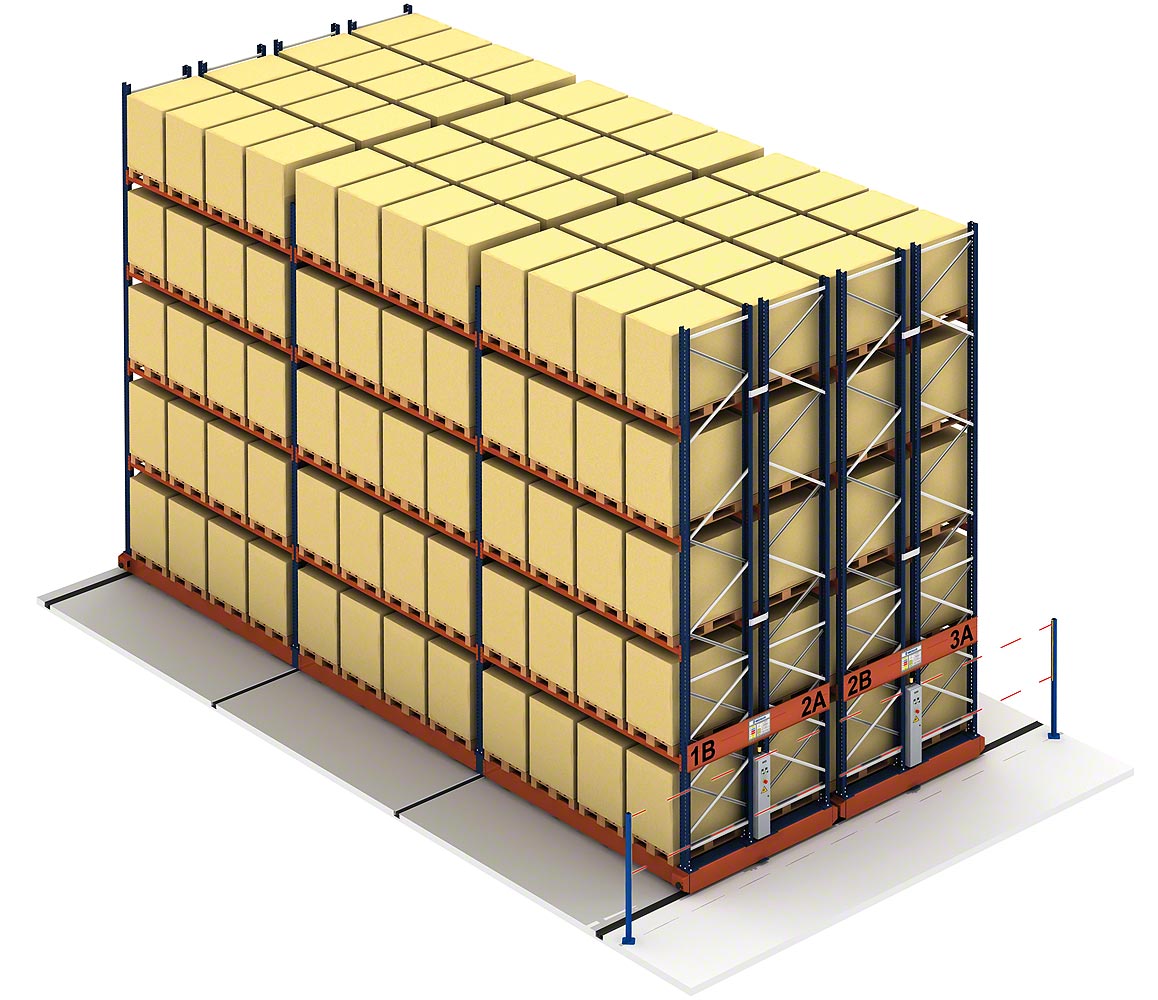

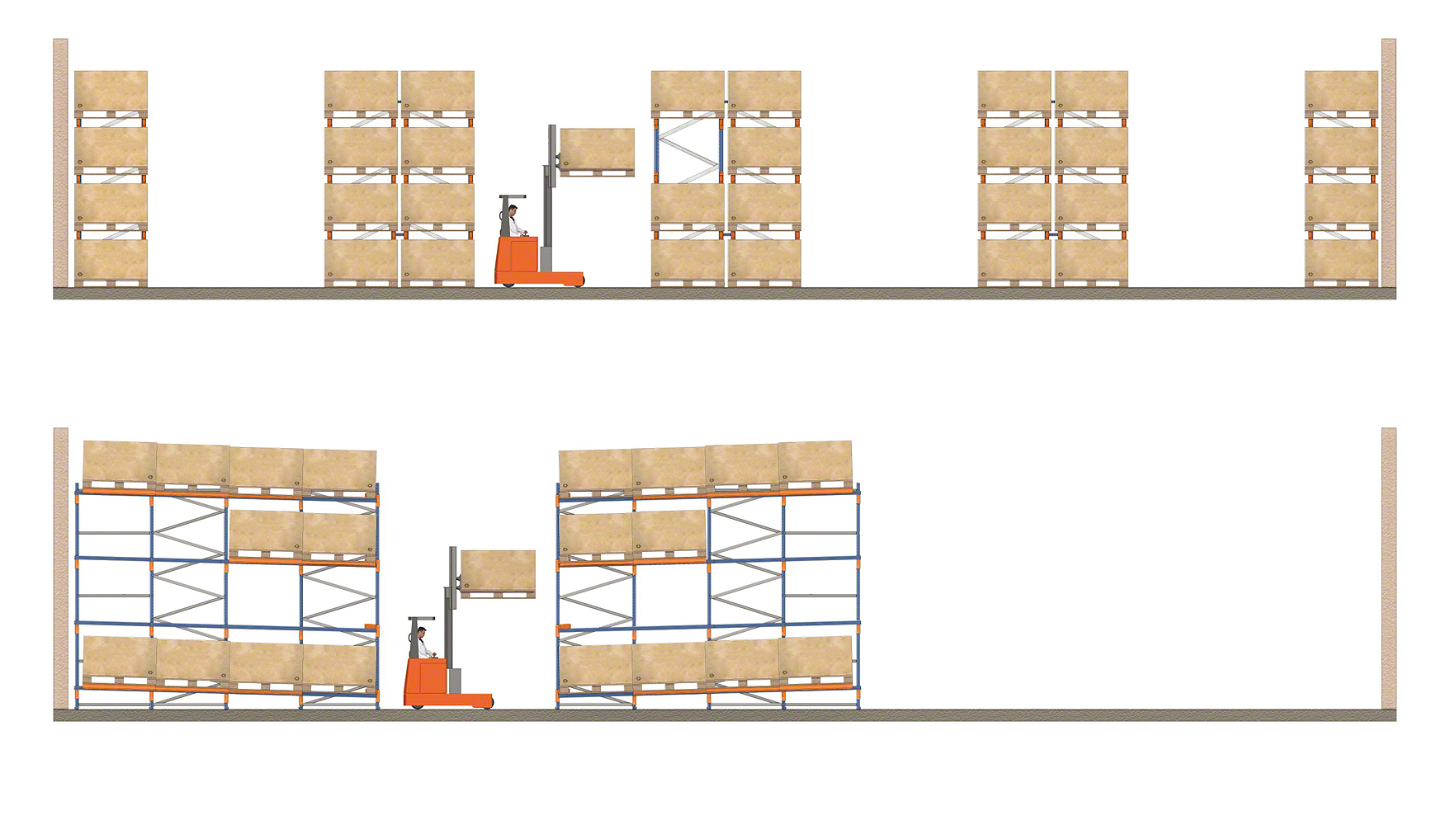

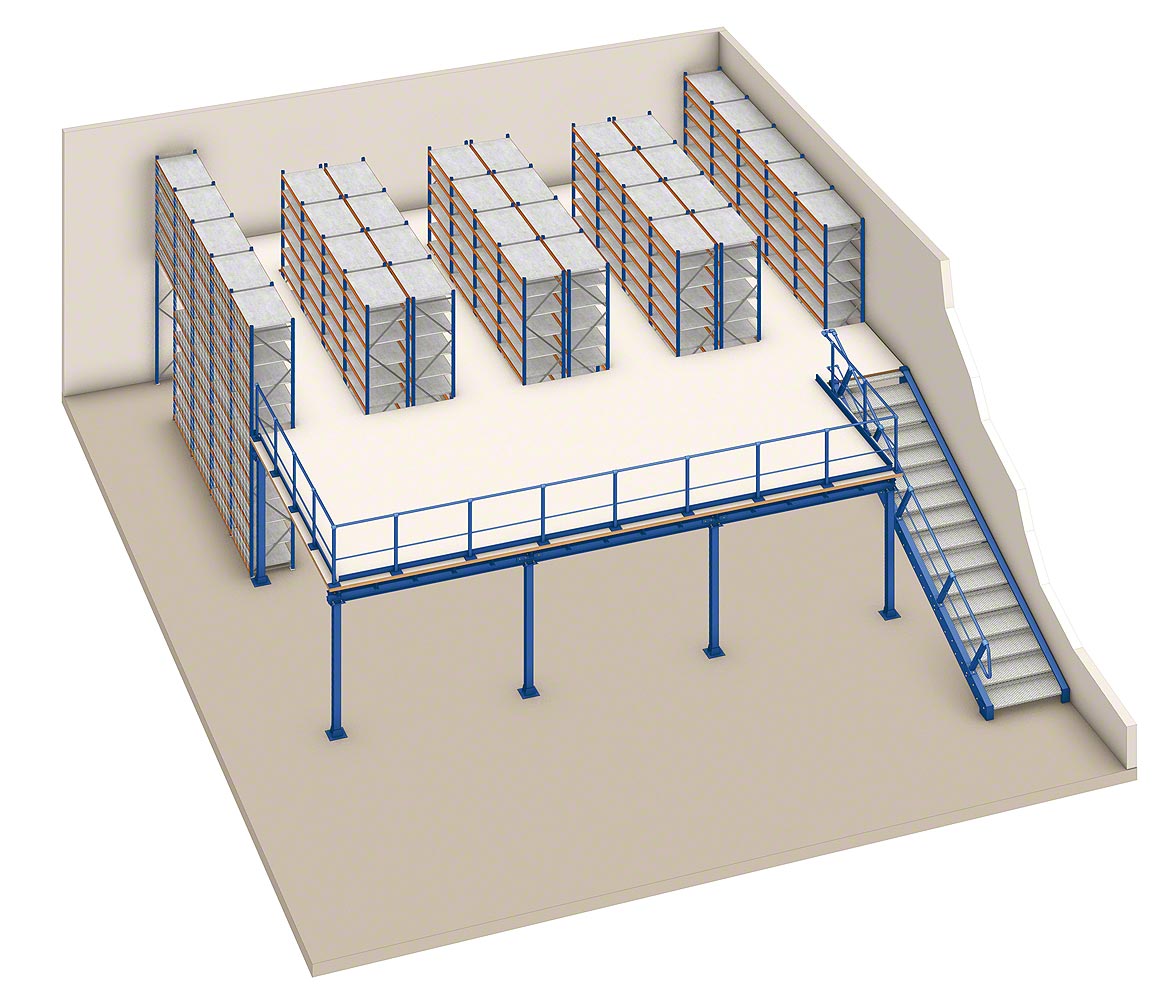

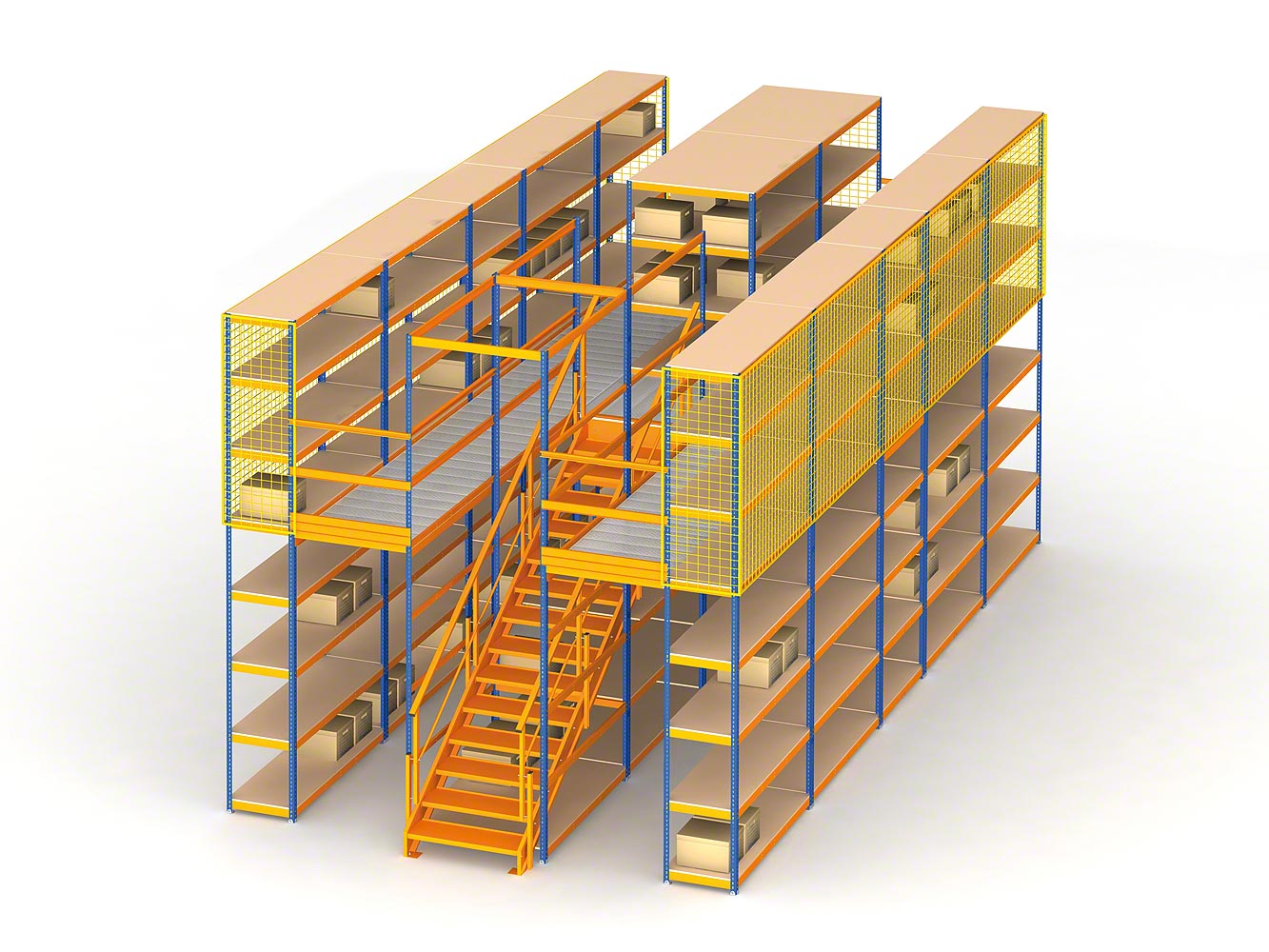

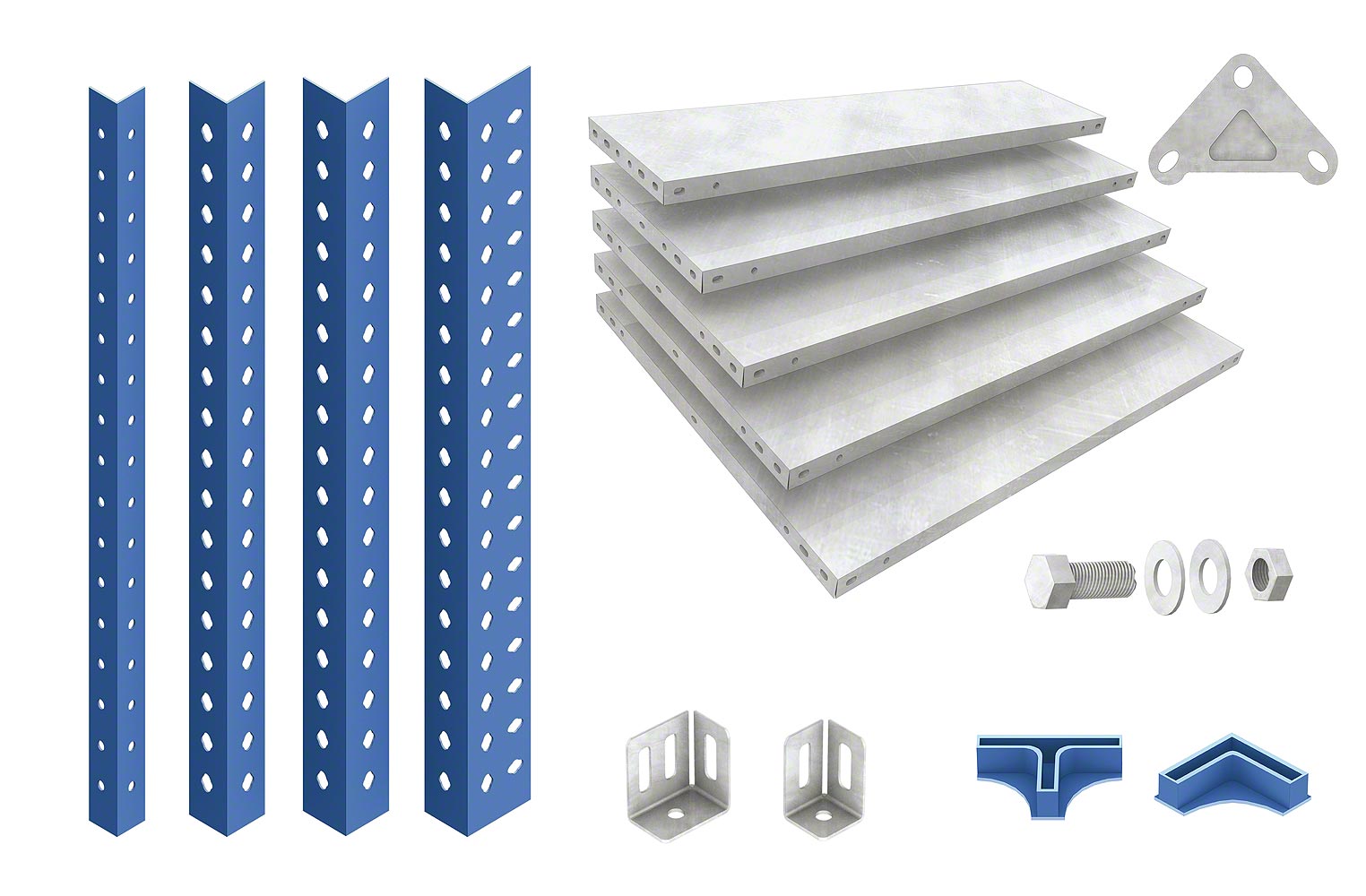

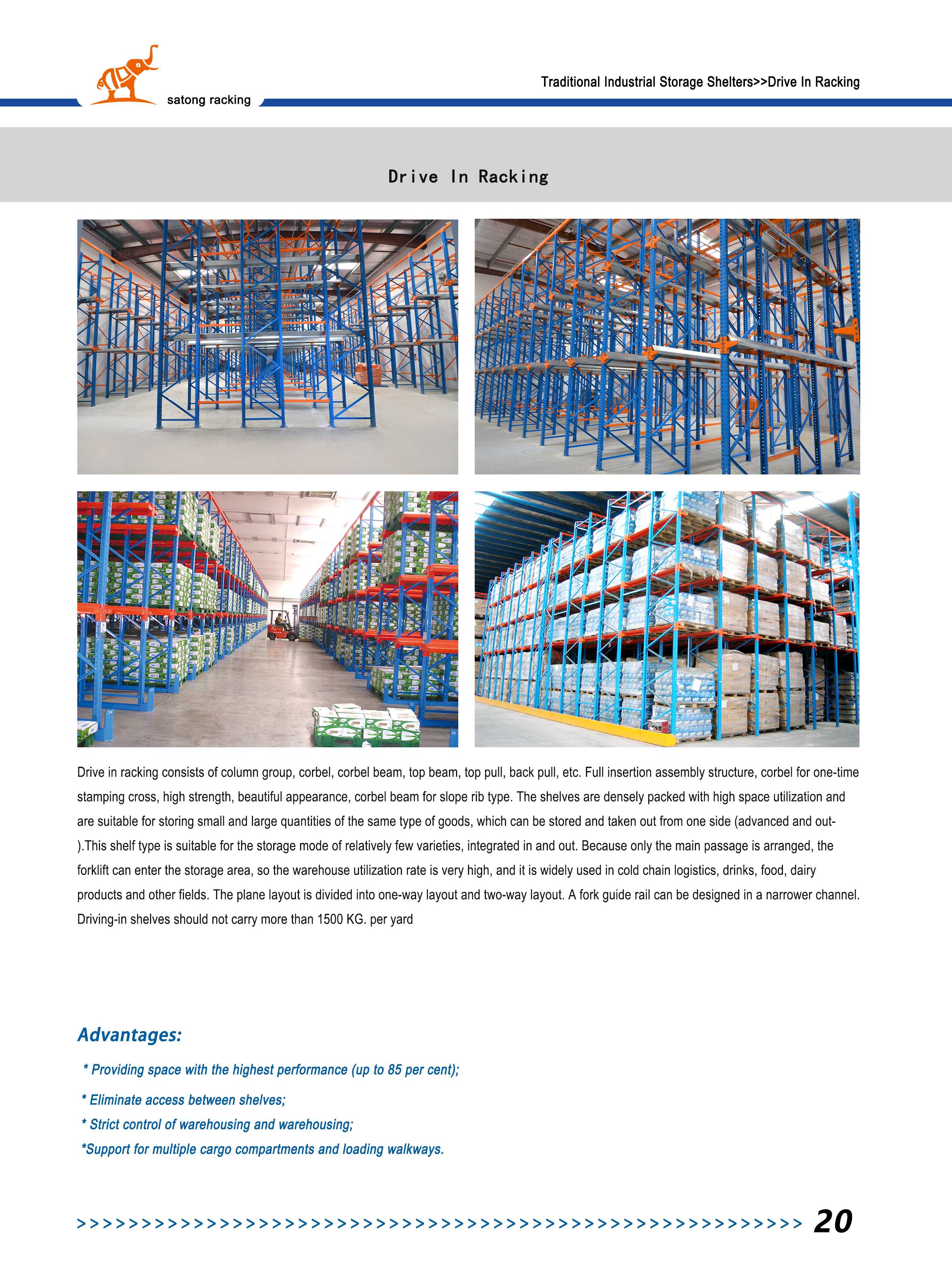

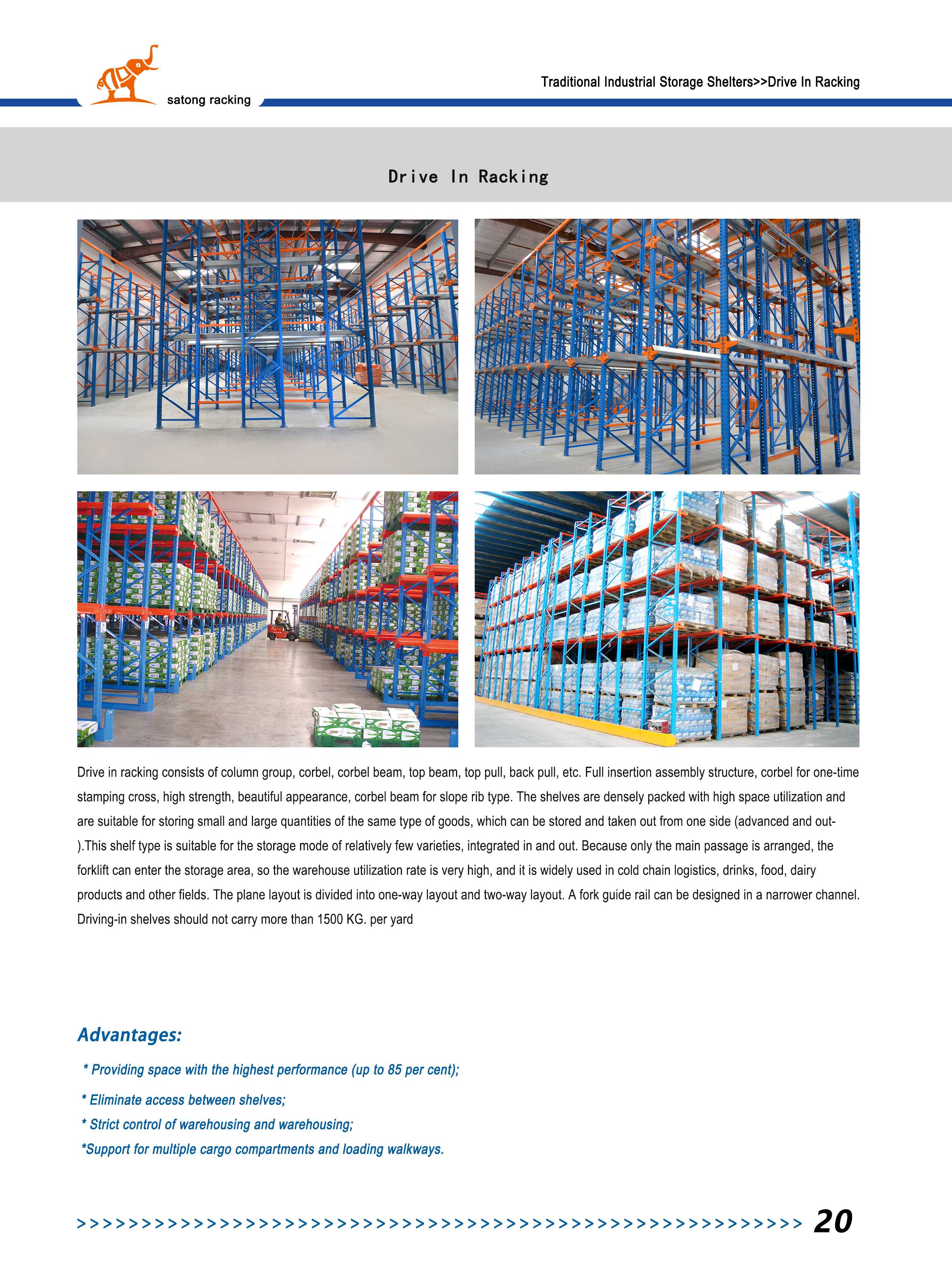

Drive in racking consists of column group, corbel, corbel beam, top beam, top pull, back pull, etc. Full insertion assembly structure, corbel for one-time stamping cross, high strength, beautiful appearance, corbel beam for slope rib type. The shelves are densely packed with high space utilization and are suitable for storing small and large quantities of the same type of goods, which can be stored and taken out from one side (advanced and out).This shelf type is suitable for the storage mode of relatively few varieties, integrated in and out. Because only the main passage is arranged, the forklift can enter the storage area, so the warehouse utilization rate is very high, and it is widely used in cold chain logistics, drinks, food, dairy products and other fields. The plane layout is divided into one-way layout and two-way layout. A fork guide rail can be designed in a narrower channel. Driving-in shelves should not carry more than 1500 KG. per yard

Drive In Racking

Drive in racking consists of column group, corbel, corbel beam, top beam, top pull, back pull, etc. Full insertion assembly structure, corbel for one-time stamping cross, high strength, beautiful appearance, corbel beam for slope rib type.

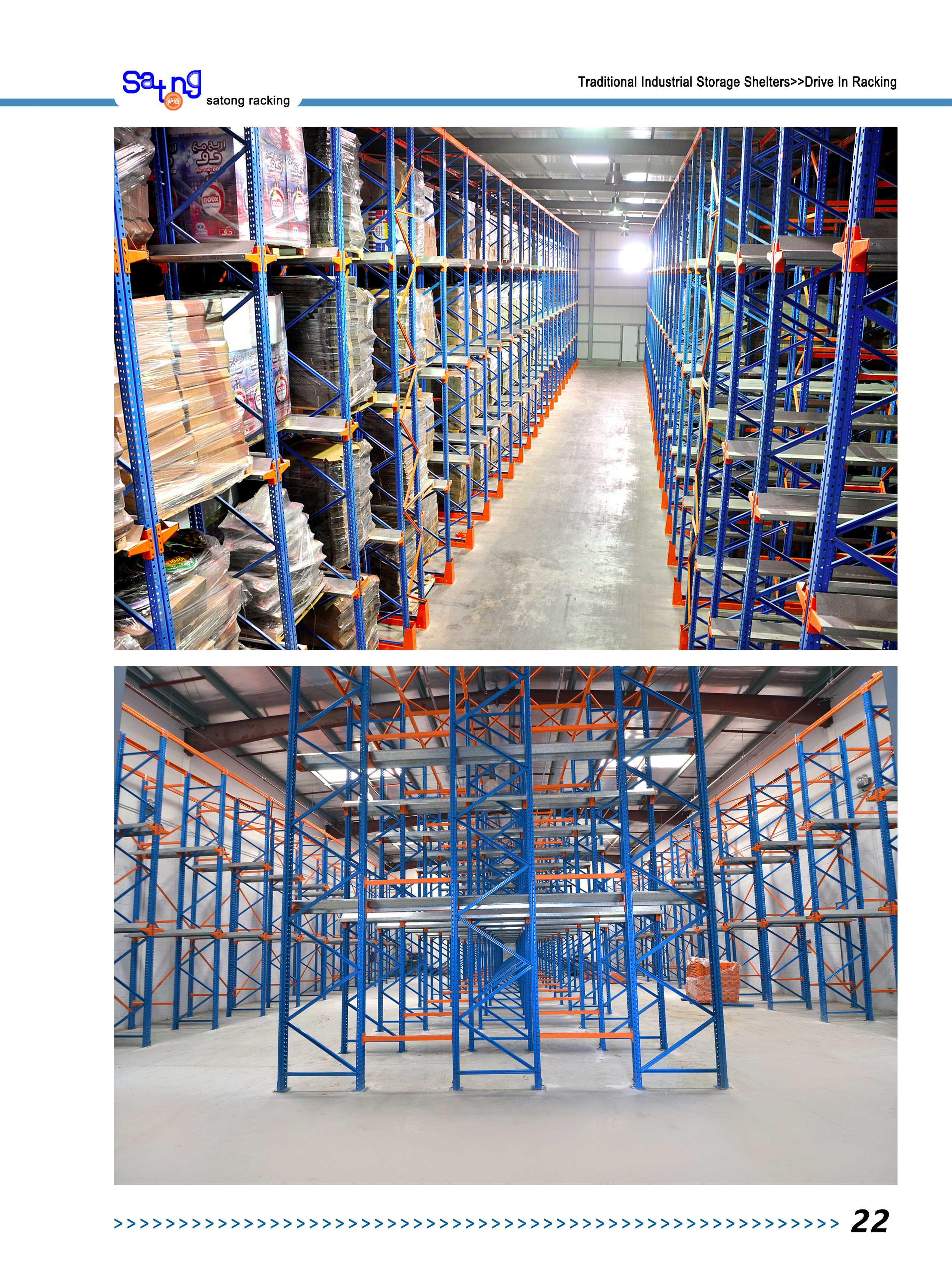

Drive In Racking

Associated Website: